Le nuove Digital Glue SCD1990 LE (per alte temperature) e SCD1995 LE (per basse temperature) ampliano la gamma di prodotti LOW EMISSION, già composta da inchiostri e materiali digitali innovativi.

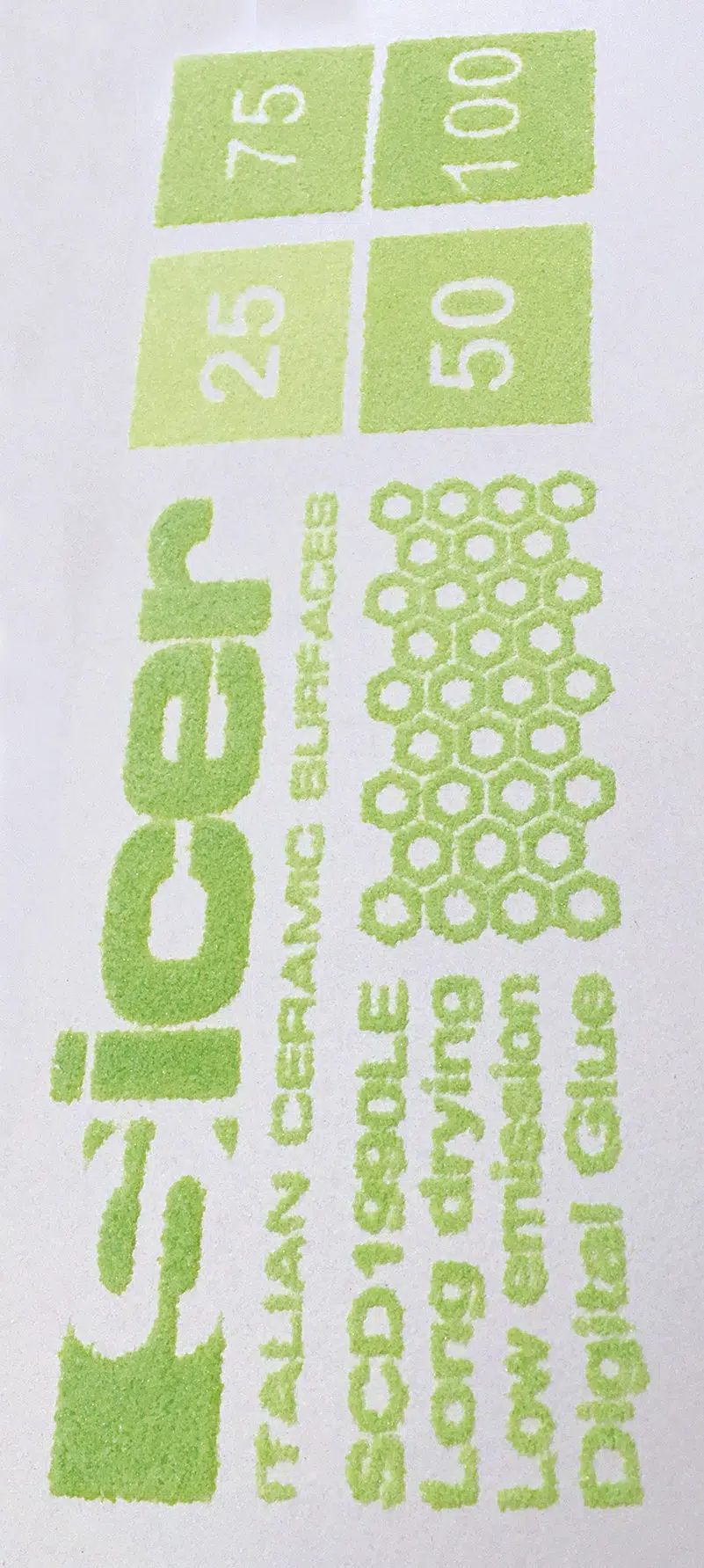

Il progetto “brevettato” LOW EMISSION di Sicer mira a ridurre sensibilmente l’impatto ambientale, utilizzando una speciale miscela di solventi ultra-raffinati che garantiscono una perfetta qualità di stampa.

La serie .LE, rispetto a tutti i migliori prodotti a basse emissioni oggi sul mercato, ha eliminato efficacemente le emissioni di odori e ridotto le emissioni di formaldeide di oltre il 50%

La colla digitale, abbinata a graniglie speciali, consente di ottenere superfici ed effetti diversi, riducendo al minimo i difetti e la porosità superficiale.

Il Laboratorio R&D Digitale di Sicer propone una nuova serie di 3 COLLE DIGITALI A BASE ACQUA , completamente inodori e a bassa emissione.

Tre diverse tipologie di colle a BASE ACQUA, due lucide e una opaca, che integrano sostenibilità e alte prestazioni.

Le prime sono la colla naturale SCD3001H, contenente flussante, e la colla naturale SCD3005H, senza flussante . Totalmente inodori e a basse emissioni, con un elevato potere adesivo, racchiudono caratteristiche tecniche estremamente performanti.

Sicer ha sviluppato la nuovissima colla opaca a BASE ACQUA SCD3100H , che contiene un fondente specificamente studiato per creare un effetto ceramico opaco.

Oltre alle caratteristiche di potere incollante, distensione, di abbattimento delle emissioni al camino e di ottima qualità di stampa, questa colla può essere utilizzata in abbinamento a grane opache , alle quali conferisce distensione, trasparenza e un basso grado di lucido.

Quality,

technical research

and service.

You might also be interested in

Fill out the spaces below and send your message.

Realize your projects with our materials.

Contact nowWater-based digital glues are more sustainable, reducing emissions significantly and limiting evaporation and degassing defects during firing

Yes, water-based glues require more careful and frequent maintenance of the digital bars due to their higher dryness compared to solvent-based products

Yes, water-based glues are suitable for various supports and ceramic productions, including both full-field grit applications and digital graphics

Yes, water-based glues can be applied over solvent-based ink decorations, maintaining high definition and good surface coverage without water repellence defects

Yes, water-based glues are designed for intermittent use, with support from technicians and maintenance protocols to keep the bars in optimal condition during low usage periods

How digital inks are revolutionizing the ceramic industry

Ceramic decoration: the use of Sicer grits

Ecological glue: the future is green, even in the world of ceramics

Fight against climate change and sustainability: Sicer’s answer

The year 2020 in Sicer: new products, pro-environment policies and constant trust in the future, despite everything.

Materials for a sustainable future: Sicer’s eco-friendly ceramic inks and glues

Sustainability as a priority: Sicer’s first sustainability report

Update your browser to view this website correctly.

Update my browser now